At PetroChem Valve, we know that equipment issues can’t wait. That’s why we provide both emergency repair services and preventative maintenance programs, backed by our state-of-the-art in-house machine shop. From valves to actuators, our experts handle it all with precision and efficiency.

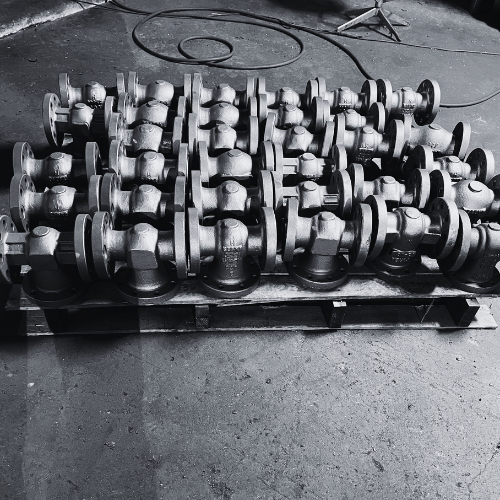

Everything we do is performed in-house at our 65,000 sq. ft. facility, equipped with advanced machining, welding, coating, and testing capabilities. By keeping every step under one roof, we guarantee faster turnaround times, strict quality control, and custom solutions built to order.

Repairs

When valves or actuators fail, downtime is costly. Our technicians provide 24/7 emergency repair services, ensuring your equipment is restored quickly and safely. We service all major valve types — gate, globe, check, ball, butterfly, plug, and more — along with actuators. Whether it’s a leaking seal, worn trim, damaged body, or actuator malfunction, we deliver fast, dependable results.

Repair Highlights:

- Custom repairs to restore or improve function

- 24/7 emergency response

- Complete in-house machining, welding, and coating

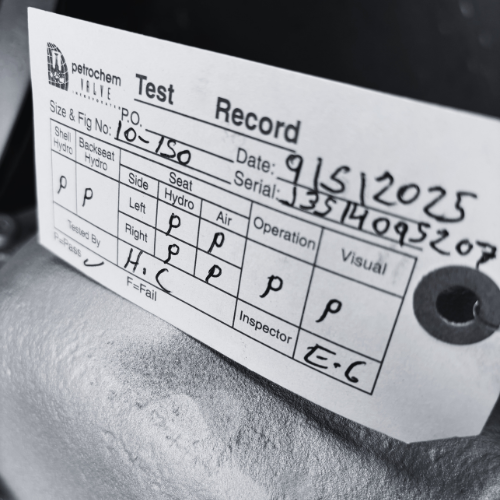

- Hydrostatic, gas, and performance testing

Maintenance

Preventing problems before they occur is the best way to protect your bottom line. Our maintenance programs are tailored to your system’s needs, helping you avoid unplanned downtime and costly failures. Services include inspections, cleaning, lubrication, part replacements, and performance testing — keeping your valves and actuators reliable in any environment.

Maintenance Highlights:

- Certified testing for guaranteed reliability

- Scheduled inspections and servicing

- Extended valve and actuator service life

- Customized programs for your facility

Testing

At PetroChem Valve, every valve we handle is held to the highest standards of safety, reliability, and performance. Our in-house testing capabilities ensure that all valves — whether new, repaired, or rented — meet strict industry requirements before they reach your operation.

Our Testing Capabilities Include:

- Hydrostatic & Gas Testing

- Magnetic Particle & Ultrasonic Testing

- Functional Testing with Air, Water, Nitrogen, Helium, and Kerosene

- Actuation & Cycling Verification

With our full-service repair and testing facility, we can certify valves for the most demanding applications across petrochemical, refining, power generation, wastewater, and other industries.

When you partner with PetroChem Valve, you get peace of mind knowing your valves are proven safe, leak-free, and ready for service.